TUBULARTM

TUB-AX

A better equivalent of the XRUHAKXS cable

cost reduction by 15% – 20%

A better equivalent of the XRUHAKXS cable

cost reduction by 15% – 20%

Lower weight

better cooling

Smaller radius

of bend

up to 20% lower

purchase cost

prolonged current carrying capacity

of the power conductor

Higher short-circuit current rating

Our offer

dysponujemy odpowiednim certyfikatem

(Certificate of the Warsaw Institute of Energy for conformity with the Polish standard PN HD 620 S2:2010),

Test report BBJ-SEP for the TUBULAR™TUB-AX cable

request the certificate

Our offer

The fittings recommended for the SICAME’s TUBULAR™TUB-AX cables, both joints and heads (indoor and outdoor), for all conditions, used in all industries

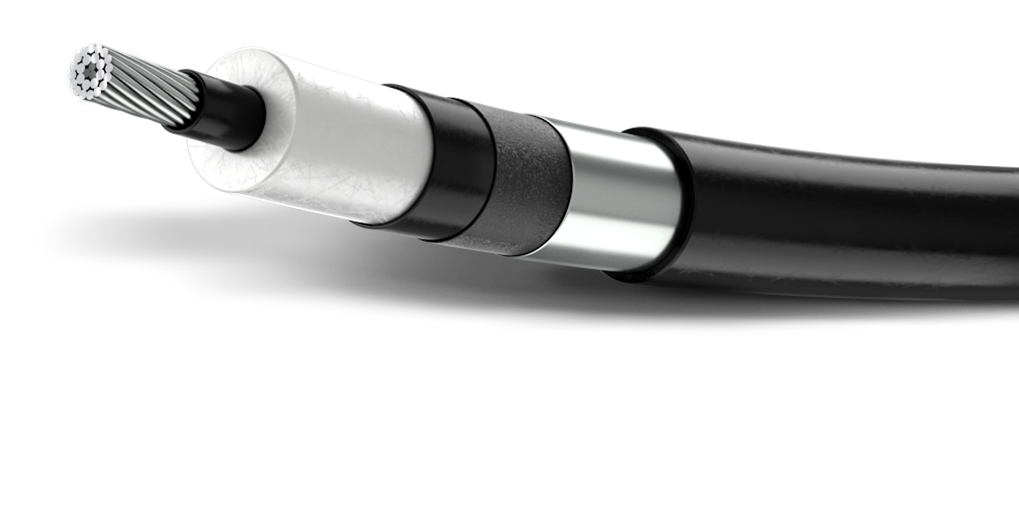

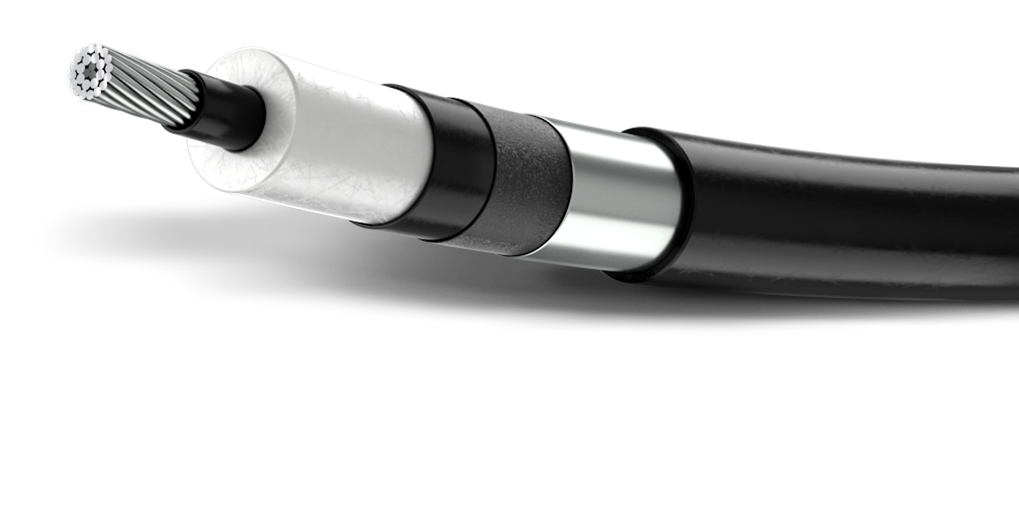

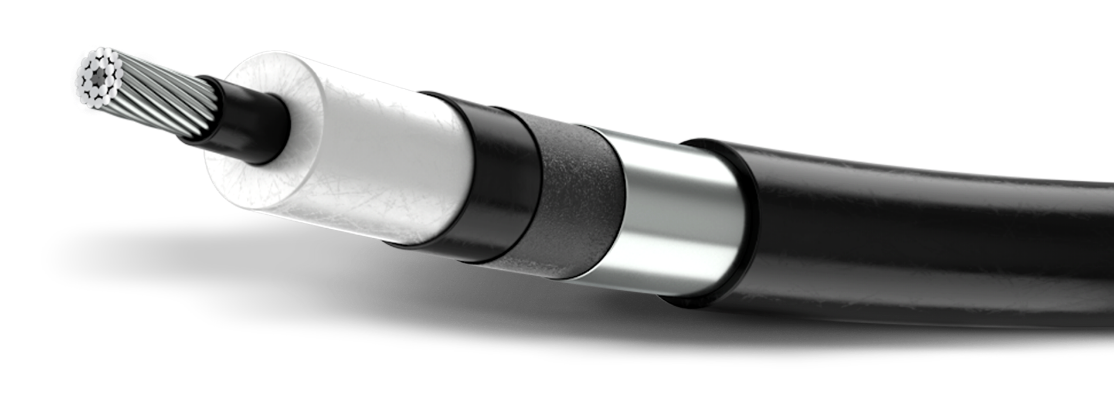

Working Vein

Class 2 aluminium

Screen on the vein

Semi-conductive PE

Insulation

Cross-linked PE

Screen on insulation

Semi-conductive PE

Screen surround

Water-tight semi-conductive band

The return vein

Special aluminium tubing

Radial seal

Al band with PE copolymer, lengthwise

Coat

Thermoplastic PE

Test voltage

3.5U0 /5 mins

Partial discharge intensity

max 2pC/2U0

Core temperature for long-term load

+90°C

Maks. temp. żyły roboczej przy zwarciu 5 sek.

+250°C

Maximum pulling force for the working strand

30xS (S=wire core size), kN [kN]

The lowest permissible temperature of cables during laying

-20°C

Min.bending radius

13 d (d = cable O.D.)

Zastosowanie

Electrical power transmission over lines with a maximum rated voltage of U0/U (Um) = 3.6/6 (7.2) kV; 6/10 (12) kV; 8.7/15 (17.5) kV; 12/20 (24) kV; 18/30 (36) kV

Alphanumerical encoding of the TUBULAR™TUB-AX XRUHAKXS cable

Cable (K), for electrical power application with aluminium core (Al), radial field (H),

XLPE [cross-linked polyethylene] insulation (XS), sealed lengthwise (U) and radially (R),

thermoplastic polyethylene sheath (X)